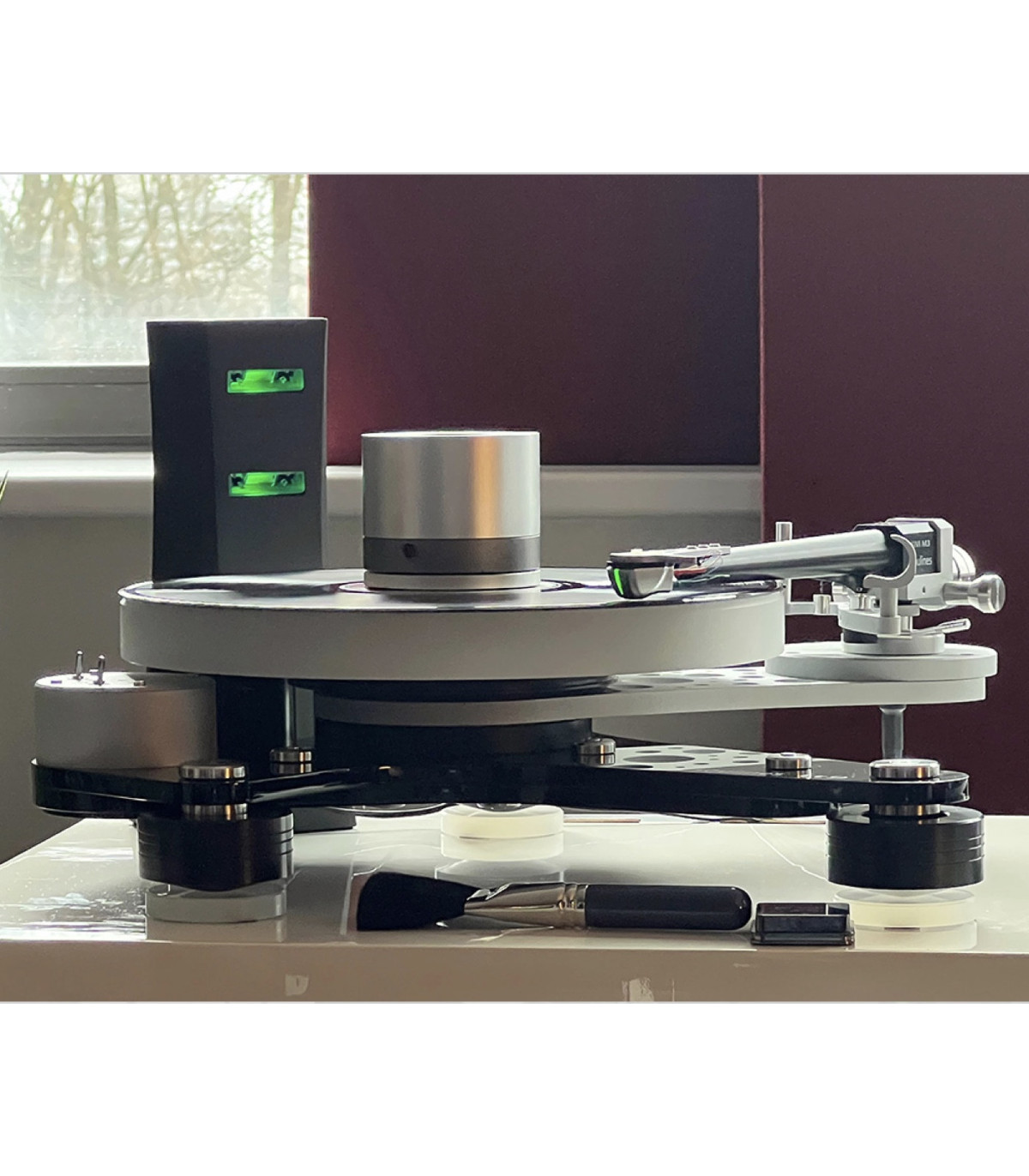

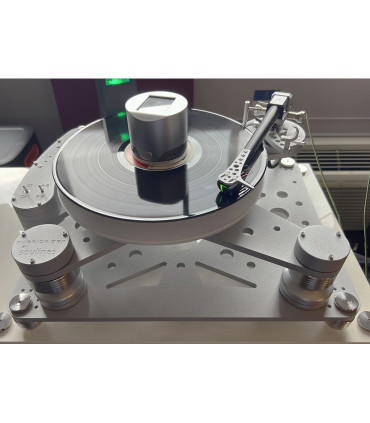

Soulines TT9 Turntable with KiVi M3 Tonearm

Soulines tt9 Turntable with KiVi M3 Tonearm

The new tt9 turntable model is designed based on the advanced engineering solutions implemented in Soulines’ top-tier models, the tt42 and Kubrick DCX. Differently shaped elements, precisely CNC-machined and crafted from materials such as cast Acrylic, Delrin (POM-engineering plastic), and aluminum, form a light yet highly rigid assembly.

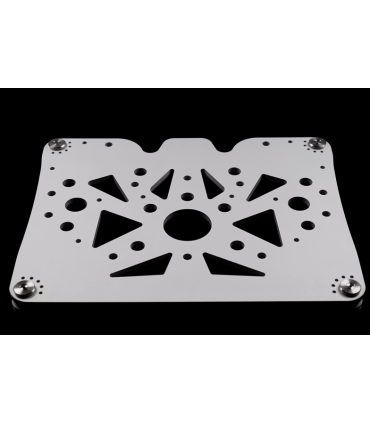

This solid yet lightweight construction plays a crucial role in preventing sound-damaging resonance energy from being stored within the assembly. With no excessive mass to trap vibrations, resonances are effectively dissipated. The dimensions and shape of the plinth and sub-plinth elements—including the arrangement of the holes—were optimized using the Golden Ratio and Fibonacci sequence, ensuring uniform vibration damping and reducing the moment of inertia across all three planes toward the center of mass.

Continuing Soulines’ tradition, the tt9 offers compact, high-quality design delivering performance that approaches the high-end segment, while remaining extremely user-friendly. Setup is intuitive and straightforward, requiring no special tools or extensive technical experience.

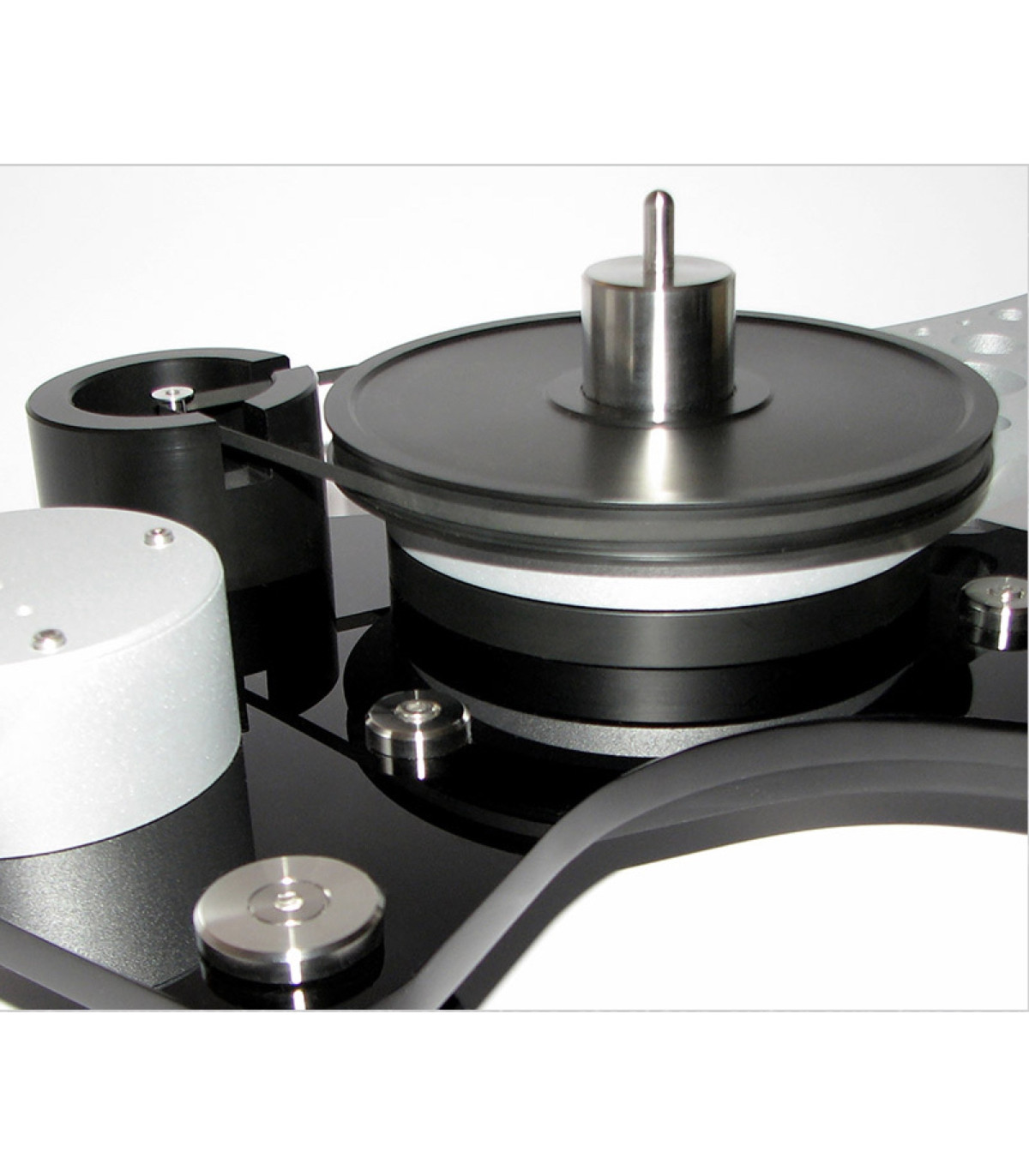

The main bearing is of the inverted type, made of solid stainless steel with a brass spindle sleeve and a Derlin thrust pad. The highly polished stainless steel spindle supports a captive hardened steel ball bearing. The sub-platter, precisely machined from Derlin, is rigidly fixed to the main bearing.

The 30mm-thick platter, weighing 2.6kg, is CNC-machined from cast Acrylic and, paired with the advanced main bearing, ensures smooth rotation with no rumble or noise. A 1.0mm recess is carved into the top surface to accommodate LP record labels, allowing the record to lay perfectly flat. For improved grip, users may employ the included tt Clamp, which presses the LP firmly onto the platter for optimal sonic performance.

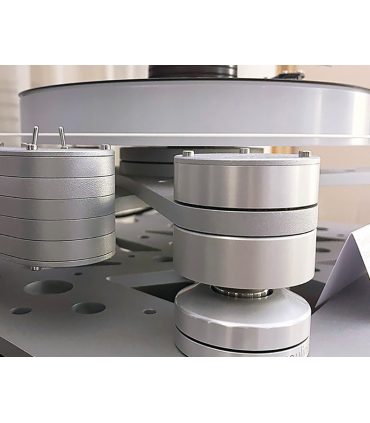

The aluminum arm-board and main bearing are mounted directly to the aluminum sub-plinth, which is 3-point coupled to the main plinth made of cast Acrylic and Derlin via rubber-cork washers of different diameters and thicknesses. This design maximizes performance while minimizing acoustic breakthrough. The motor assembly, machined from Derlin, is rigidly fixed to the main plinth.

The drive system features the same high-quality DC motor used in Soulines’ higher-end models. It is electronically controlled for easy operation and precise fine speed adjustment at both 33 and 45 RPM. Switching between speeds and powering the unit on/off is done via simple toggle switches.

The turntable rests on three height-adjustable cones, precision-machined from Derlin, for easy leveling and optimal coupling to the supporting surface. These cones are mounted using the same rubber-cork washers as the sub-plinth to further control vibration transmission.

A Soulines KiVi M3 tonearm comes pre-mounted on the tt9. With the addition of a quality phono cartridge, it provides an excellent vinyl playback system.

Specifications

- Drive: Electronically controlled high-quality DC motor

- Speeds: 33.33 and 45.00 RPM with fine speed adjustment feature

- Bearing: Advanced inverted bearing; CNC machined from solid stainless steel with brass sleeve insert and Derlin thrust pad; polished stainless steel spindle with captive hardened steel ball bearing

- Platter: 30mm thick, 2.6kg, machined from cast Acrylic

- Construction: Multi-layered plinth in cast Acrylic and POM (Derlin) with 3-point coupled aluminum sub-plinth

- Finish: Shiny black and powder-coated silver aluminum color

Extras included:

-

SA Cover – Acrylic dust cover

-

tt Clamp – Record clamp

-

Protractor LP – Precision printed cartridge alignment tool featuring Baerwald, Loefgren, and Stevenson geometries

Power:

AC 230V/50Hz; DC input 12V/300mA

Dimensions:

440 x 355 x 170 mm (W x D x H) overall

400 x 330 mm (W x D) footprint

Net weight:

10 kg

Packaging dimensions:

510 x 410 x 310 mm (W x D x H)

Shipping weight:

12 kg

Soulines at a glance (pronunciation: /ˈsuː.laɪnz/ - "Sù-lains")

The Story

In mid-2009, a group of musicians and discerning music lovers—with solid backgrounds in recording, mixing, production, and audio restoration on one side, and skilled mechanical engineers on the other—decided to turn their long-standing hobby and passion for modifying, upgrading, designing, and building turntables into a professional venture.

They founded the company tt recycled (turntable recycled), www.ttrecycled.com, with the primary goal of offering upgrade and modification services for turntables, alongside recycling and redesign.

Before long, Soulines established itself as a local specialist in turntable solutions, successfully recycling, redesigning, and enhancing numerous models for customers in the area. In addition to commissioned projects, the team developed several original turntables based on their own concepts. These designs quickly gained popularity among local audiophiles, culminating in the Best Sound Award at the Belgrade Hi-Files Show in 2010.

The Idea

Driven by the ambition to create a turntable of their own design, Soulines aimed to produce a high-quality product that would truly stand out. The goal was to merge musicality and visual elegance into an electromechanical object capable of faithfully reproducing vinyl records. At the same time, the focus was on ease of use and straightforward setup.

The result was the Hermes DCX turntable.

Following extensive listening tests and the enthusiastic reception at the Belgrade Hi-Files Show in 2011, Soulines decided to launch the Hermes DCX internationally.

Thus, Soulines was born.

The Design Philosophy

The core design philosophy is that every component of the turntable is equally important; it makes no sense to emphasize certain elements—such as platter mass or chassis weight—if the rest of the components do not match that standard. There is no value in using extravagant parts or overly complex solutions.

Generally, the best results come from intelligent, simple engineering, careful material selection, and high-quality components not restricted by cost-cutting compromises.

Soulines turntables are essentially handcrafted, supported by advanced technologies like CAD, 3D SolidWorks design software, and precision CNC machining.

All materials are carefully selected based on their acoustic and mechanical properties. Critical components such as the platter, bearing, and spindle are manufactured individually and matched to work in perfect harmony, rather than being mass-produced.

For damping, various rubber and cork feet are used in different shapes and thicknesses. Rigid parts of the system are coupled with layers of different materials to minimize resonance to the lowest possible levels.

All Soulines turntables feature belt-drive, DC motors, inverted bearings, and non-metallic platters.

Before final assembly, every component is inspected, hand-finished, and assembled with a high degree of precision to ensure outstanding performance. Finished products undergo rigorous testing before packaging and shipping.

Soulines – Analog Perfection, Beyond Industrial Compromise

Soulines embodies the pure essence of vinyl—a fusion of flawless design and extraordinary sonic performance. Each Soulines turntable is crafted to deliver a unique audio experience where every detail, every note, and every nuance is rendered with the kind of precision and depth that only analog can provide.

Guided by a philosophy that blends traditional craftsmanship with cutting-edge technology, Soulines creates turntables that are not just listening devices, but true works of art. Made from top-quality materials with obsessive attention to detail, every model is designed to reveal the authenticity of sound and the timeless beauty of vinyl.

The mission of Soulines is simple: to bring listeners an experience that goes far beyond mere music playback—transforming it into a rich, emotional journey full of depth, presence, and soul.

Leave a review