B-Stock product, (read below) in excellent condition with original packaging, 2 year warranty.

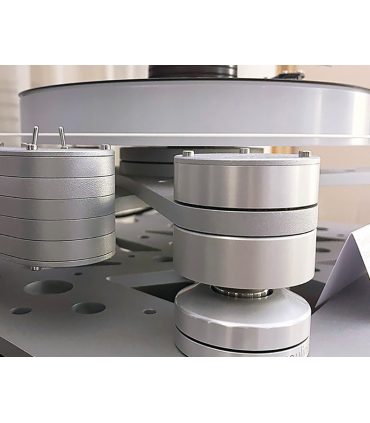

Soulines TT-Clamp Turntable Stabilizer

The turntable clamp, also known as a TT Clamp or record clamp, can be a very useful accessory, especially when playing slightly warped records. Instead of adding weight and causing excessive wear to the main bearing and the turntable drive system, this type of clamp applies force only to the spindle and the platter, securely clamping the record to the platter. This stabilizes the record and improves playback performance by tightening frequencies across the spectrum and reducing any resonance that may occur as the stylus tracks the groove of an unsecured record.

In addition to its obvious function of securing and stabilizing the record, when designing the Soulines clamp, the goal was to create optimal mechanical connections between the clamp, spindle, record, and platter by using materials suited to the task based on their mechanical characteristics—such as hardness, stiffness, softness, and damping properties.

The clamping disk is made of POM (polyoxymethylene), a rigid plastic with excellent damping characteristics; the collet chuck or clamping sleeve is made from brass, which is softer than aluminum, stainless steel, and other hard materials commonly used for turntable spindles, allowing for a good grip on the spindle; the locking nut is made from aluminum, which is stiffer than brass and thus ideal for the tightening function.

Depending on the design of the platter/mat and the particular record’s thickness and warp condition, the Soulines clamp requires the user to place a washer around the spindle before placing the record on the platter and securing the clamp. For this reason, two pairs of washers with 17mm and 23mm diameters—made from cork and rubber-cork—are included, allowing the user to experiment and choose the most suitable one (or a combination of both) for the best results.

Soulines at a glance (pronunciation: /ˈsuː.laɪnz/ - "Sù-lains")

The Story

In mid-2009, a group of musicians and discerning music lovers—with solid backgrounds in recording, mixing, production, and audio restoration on one side, and skilled mechanical engineers on the other—decided to turn their long-standing hobby and passion for modifying, upgrading, designing, and building turntables into a professional venture.

They founded the company tt recycled (turntable recycled), www.ttrecycled.com, with the primary goal of offering upgrade and modification services for turntables, alongside recycling and redesign.

Before long, Soulines established itself as a local specialist in turntable solutions, successfully recycling, redesigning, and enhancing numerous models for customers in the area. In addition to commissioned projects, the team developed several original turntables based on their own concepts. These designs quickly gained popularity among local audiophiles, culminating in the Best Sound Award at the Belgrade Hi-Files Show in 2010.

The Idea

Driven by the ambition to create a turntable of their own design, Soulines aimed to produce a high-quality product that would truly stand out. The goal was to merge musicality and visual elegance into an electromechanical object capable of faithfully reproducing vinyl records. At the same time, the focus was on ease of use and straightforward setup.

The result was the Hermes DCX turntable.

Following extensive listening tests and the enthusiastic reception at the Belgrade Hi-Files Show in 2011, Soulines decided to launch the Hermes DCX internationally.

Thus, Soulines was born.

The Design Philosophy

The core design philosophy is that every component of the turntable is equally important; it makes no sense to emphasize certain elements—such as platter mass or chassis weight—if the rest of the components do not match that standard. There is no value in using extravagant parts or overly complex solutions.

Generally, the best results come from intelligent, simple engineering, careful material selection, and high-quality components not restricted by cost-cutting compromises.

Soulines turntables are essentially handcrafted, supported by advanced technologies like CAD, 3D SolidWorks design software, and precision CNC machining.

All materials are carefully selected based on their acoustic and mechanical properties. Critical components such as the platter, bearing, and spindle are manufactured individually and matched to work in perfect harmony, rather than being mass-produced.

For damping, various rubber and cork feet are used in different shapes and thicknesses. Rigid parts of the system are coupled with layers of different materials to minimize resonance to the lowest possible levels.

All Soulines turntables feature belt-drive, DC motors, inverted bearings, and non-metallic platters.

Before final assembly, every component is inspected, hand-finished, and assembled with a high degree of precision to ensure outstanding performance. Finished products undergo rigorous testing before packaging and shipping.

Soulines – Analog Perfection, Beyond Industrial Compromise

Soulines embodies the pure essence of vinyl—a fusion of flawless design and extraordinary sonic performance. Each Soulines turntable is crafted to deliver a unique audio experience where every detail, every note, and every nuance is rendered with the kind of precision and depth that only analog can provide.

Guided by a philosophy that blends traditional craftsmanship with cutting-edge technology, Soulines creates turntables that are not just listening devices, but true works of art. Made from top-quality materials with obsessive attention to detail, every model is designed to reveal the authenticity of sound and the timeless beauty of vinyl.

The mission of Soulines is simple: to bring listeners an experience that goes far beyond mere music playback—transforming it into a rich, emotional journey full of depth, presence, and soul.

Leave a review